Safety Excellence

Excellent safety performance (zero incident record for many consecutive years) and safety excellence are two different terms. Safety excellence is the excellence of process developed for eliminating incidents. ‘Zero incidents’ is an ultimate safety performance for any organisation however incident itself is a lagging indicator and hence cannot guarantee a sustainability in the performance. There are many important sub-processes of cultural as well as risk based safety processes. Safety excellence is systematic setting up of these sub-processes with respective performance leading indicators and monitoring performance by PDCA (Plan-Do-Check-Act) management method.

Find below the list of processes. We can provide you a guidance to develop excellent Safety Processes with leading performance indicators and integration of safety in different business processes. In case of further inquiry please fill the form on the right.

| No. | Process | Requirements |

| 1 | Management Commitment | Safety Organisation Structure headed by Director, integration of all business processes with safety, Strategy, Policies & Principles, Cardinal rules, Effective communication, periodic management review and addressing to employees, adequate budget, motivation and enforcement |

| 2 | Line management responsibility and accountability | Responsibility headed by site head, Line managers to set their responsibility and accountability, Goals, Objectives and plans, process and performance standard, Training and Development of employees, participation of employees, safety champions, safety meetings, performance review, enforcement and motivation |

| 3 | Safety staff | Safety Officer, Fire officer, fireman, trained fire squad members undertaking SHE related Legal compliance, training on hazards and safety awareness program, regular audits, site inspections, fire drills, mock drills, motivational and awareness programs, |

| 4 | Audits | Audits are scheduled adequately to ensure adherence to the systems adopted |

| 5 | Incident Investigation | Each and every incident is investigated to the root cause and fixed. |

| 6 | Management of change (Personnel, technology and Facility | Validation of change in personnel, technology and facility before executing change |

| 7 | Contractors Safety Management | Contract conditions for safety, Entry protocol, training and development, regular checks, injury record, |

| 8 | Quality Assurance | Inspection of new equipment and certifying Safety device inspection and approval on receiving equipment |

| 9 | Mechanical Integrity | Life cycle of equipment, testing, approval, Statutory inspections |

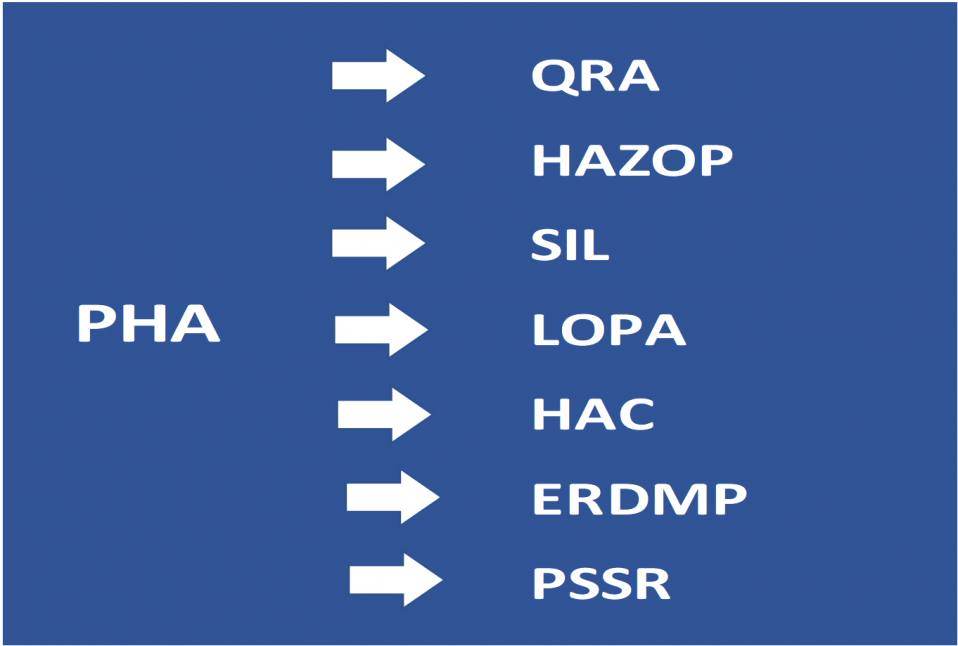

| 10 | Process Safety | Risk assessment and Process Hazard Analysis, HAZOP study, Pre-Start up safety review, availability of process document |

| 11 | Emergency preparedness | Emergency response and Disaster management plan, mock drills to ensure preparedness |

| 12 | Safe working guidelines for every trade and respective employees | Monitoring employees for their safe practices |

| 13 | Visuals | Display of safety information at adequate place |