Industries, warehouses, hotels, restaurants, commercial buildings, residential buildings, public places like railway stations etc. and offices are potentially at a risk of fatalities unless the places are designed appropriately considering the respective risk factors. Industries are at potential risk because of hazardous chemicals they handle or produce where as warehouses owing to their handling of huge storage of hazardous chemicals. Public places some times become dangerous because of uncontrolled crowd victimized by rumors. All such factors shall be considered while designing respective places with the objective of eliminating lose of lives and minimising loss of property.

A PHA is a systematic method of identifying and analyzing hazards associated with the processing or handling of highly hazardous materials. Detailed information on the PHA enables workers and employers in making decisions to improve safety and eliminate accidents.

The study analyzes potential causes (The equipment, instrumentation, human actions and SOPs, methods and other factors) and consequences (fires, explosions and toxic chemicals release) of accidents and recommends measures to reduce the probability of occurrence so that the risk is confined to the acceptable level.

A PHA team Should include engineers, operators, supervisors and other workers who have knowledge of the standards, codes, specifications and regulations which apply to the process being studied. (Source: Adapted from OSHA Process Safety Management Standard, 29 CFR 1910.119, 57 FR 6356, February 24, 1992, Appendix C)

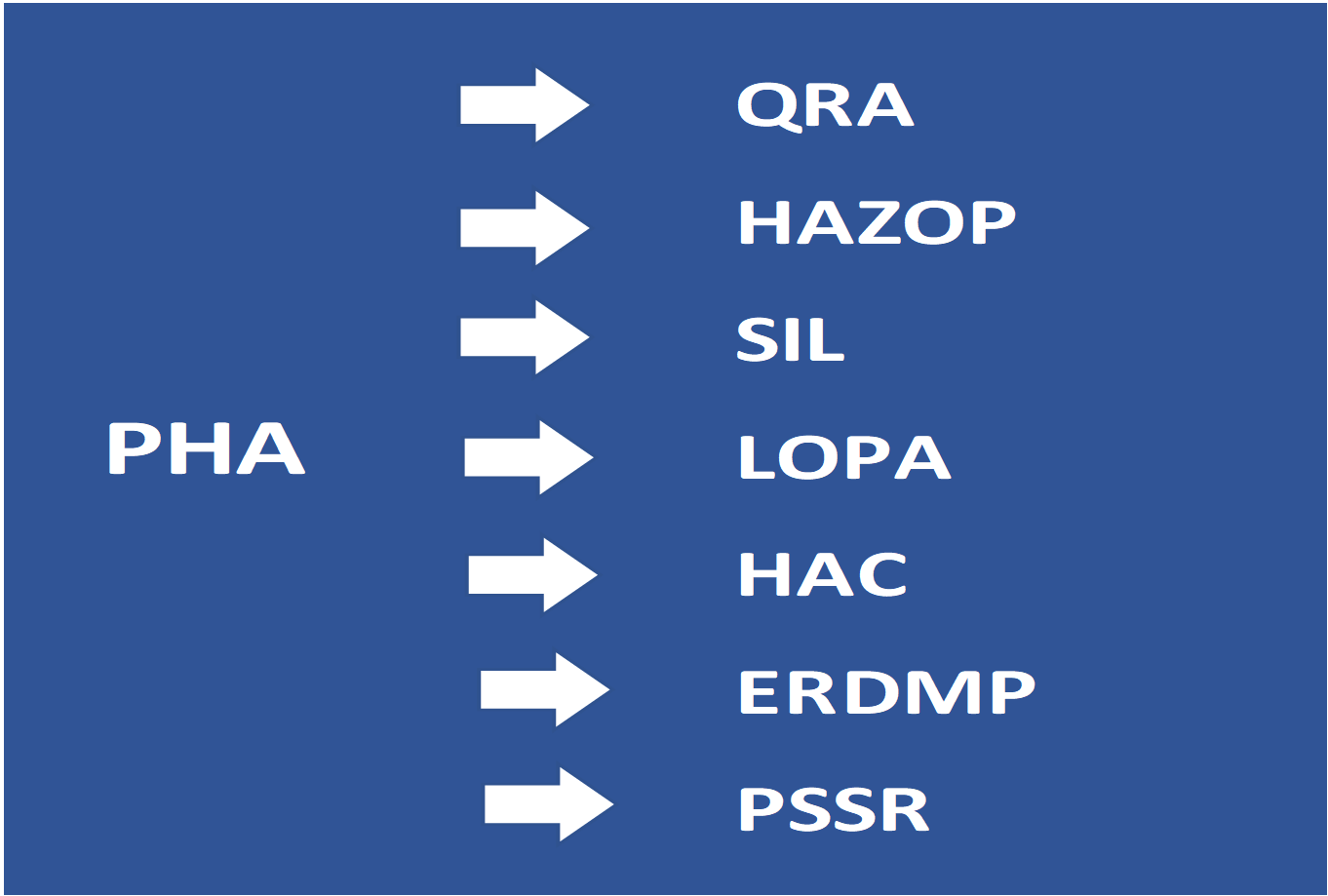

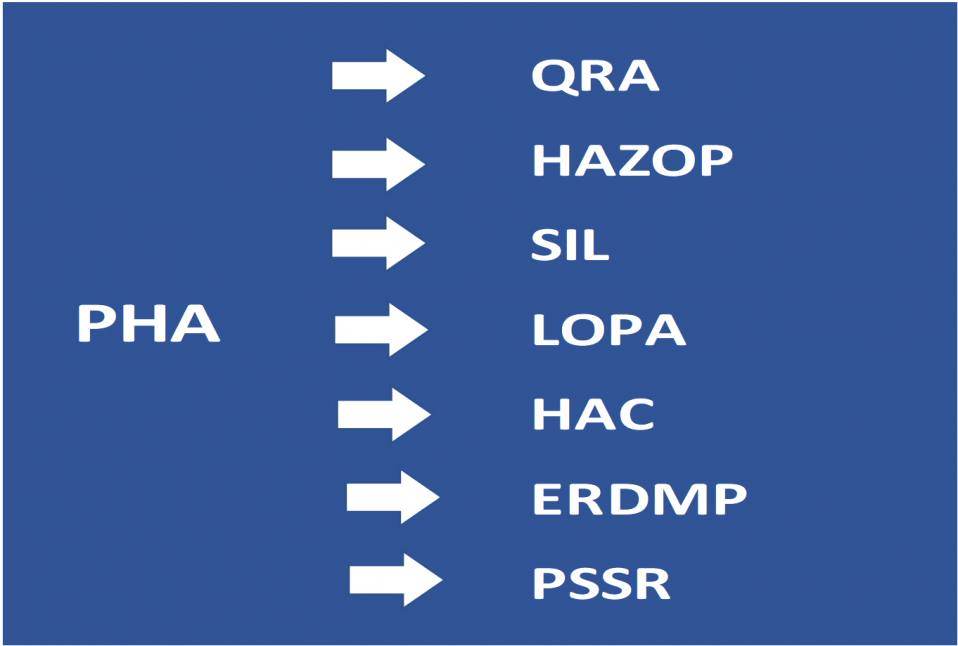

PHA may Comprise (but not limited to) Quantitative Risk Assessment (QRA), Safety Integrity Level, Layer of Protection Analysis, Hazard Area Classification, Checklists, What If, Hazard and Operability Study (HAZOP), Emergency response, Failure Mode and Effect Analysis (FMEA) and Fault-Tree Analysis (this method is also used for incident investigation)

The Most Hazardous Processes Are First: OSHA requires employers to perform a PHA on each process covered by the law. The most hazardous processes must be evaluated first. All PHAs must be completed as soon as possible. Also, all PHAs must be updated and revalidated at least every five years.