HAZOP

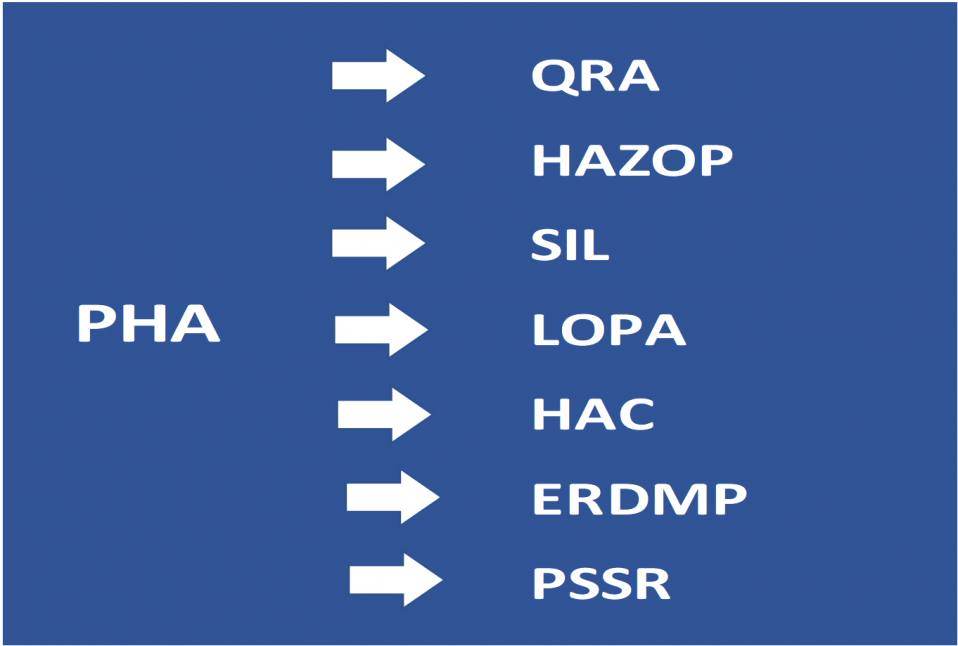

HAZOP study is a structured and systematic review of potential deviations in the process parameters and conditions. This is one of the very important method of Process Hazard Analysis (PHA). Industries with safety excellence do not proceed with procurement of equipment and instruments unless the HAZOP study report is frozen. This is because HAZOP may recommend a) change in the parameters of equipment, b) additional equipment c) rejection of some equipment d) additional controls etc and this can shatter the budget of the project. Time line pressure can push the HAZOP study to the back seat and recommendations of HAZOP study may remain on paper. Risk assessment for every deviation shall be done religiously before recommending measures. The measures recommended must bring down the risk of respective deviation to the acceptable level on the risk matrix.

The organisation shall develop a risk matrix with defined frequencies of occurrences and consequence and also a matrix for respective mechanical and instrumentation integrity level.

Mayra safety has qualified consultants with more that 25 years of experience in chemical and petrochemical industry who can complete your requirement of HAZOP study in all respect and provide you a support for implementation.

To avail the service please fill below form and click ‘SUBMIT’.